Metal etching products need to test dyne value to ensure the wetting performance and adhesion of their surface coatings.

Dyne value is an important indicator to measure the wetting performance of metal surface coatings, which reflects the ability of metal surface coatings to be wetted by liquids. By testing the dyne value, it can be determined whether the surface coating of the metal etching product has good adhesion and durability, thereby ensuring its stability and reliability during use. In addition, the dyne value test can also evaluate the anti-fingerprint and anti-oil performance of metal etching products, which also has an important impact on the appearance and user experience of the product. Therefore, metal etching products need to test the dyne value to ensure the performance and quality of their surface coatings.

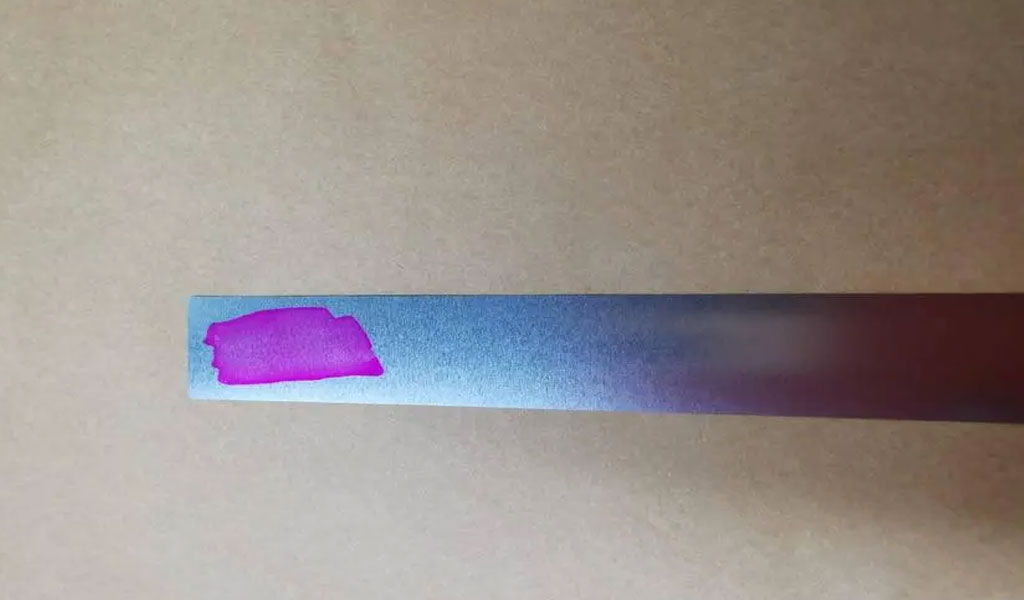

36What is the dyne value? The unit is usually millinn/m (mN/m). The higher the dyne value test result, the better the wettability of the solid surface and the cleaner the surface. The smaller the dyne value test result, the worse the wettability of the solid surface and the worse the cleanliness of the surface. The commonly used simple test method for dyne value is dyne pen or dyne liquid, including 32, 34, 36, 38, 40, 42, 44, 46, 48, 50 ~ 72, etc. Specifically, the dyne value is an indicator to measure the wetting performance of the coating on the surface of the material. The higher the value, the better the wetting performance and the stronger the adhesion.

Therefore, the dyne value requirement of 36 or above means that the wetting performance and adhesion of the coating on the surface of the material need to reach a certain level to ensure its stability and reliability during use. This standard is usually used in some high-precision and high-requirement manufacturing fields, such as aerospace, electronic manufacturing, etc. In these fields, the coating quality and performance of the material surface are crucial to the performance and quality of the product, so it is necessary to strictly control indicators such as dyne value. It should be noted that different materials and uses may have different requirements for dyne value, so the specific standard needs to be determined according to actual conditions.

We Can Take Care Of Your Metal Etching Needs.

BE-CU metal etching china company’s strength lies in our investment in chemical etching production line. Chemical etching production line are the foremost innovation to the metal etching industry.

The programmability of Chemical etching production line gives us quick and accurate repeatability. This constant replication allows for better finishes, tighter tolerances and most importantly – faster cycles for metal forming.

By engaging our etching company, you can also get the much-needed support to design your part for any specific purpose. Our team can provide custom design tips, such as ensuring consistent wall thickness and avoiding overly thick sections that can sink.

Are you designing new products for projects companies? We can help! Here at BE-CU Metal Etching China Company, we offer a reasonably priced rapid metal etching service that will allow you to make an amazing prototype that will impress your clients. Get a free project review here so we can get started for your metal etching products!

- Photo Etching for Medical Use

- Photo Etching for Metal Sign

- Photo Etching for Jewelry

- Ferric Chloride Etching Stainless Steel

- The Best Acid for Etching Steel

- The Principle And Process Flow Of PCB Etching Machine

- In The Localization Of Wafer Foundry Equipment, Etching Machines Stand Out

- How Important is the Blind Hole Rate of Filter Screens?

- The whole process of stainless steel sheet etching

- What is the Role of Aperture Diaphragms in the Field of Optics?