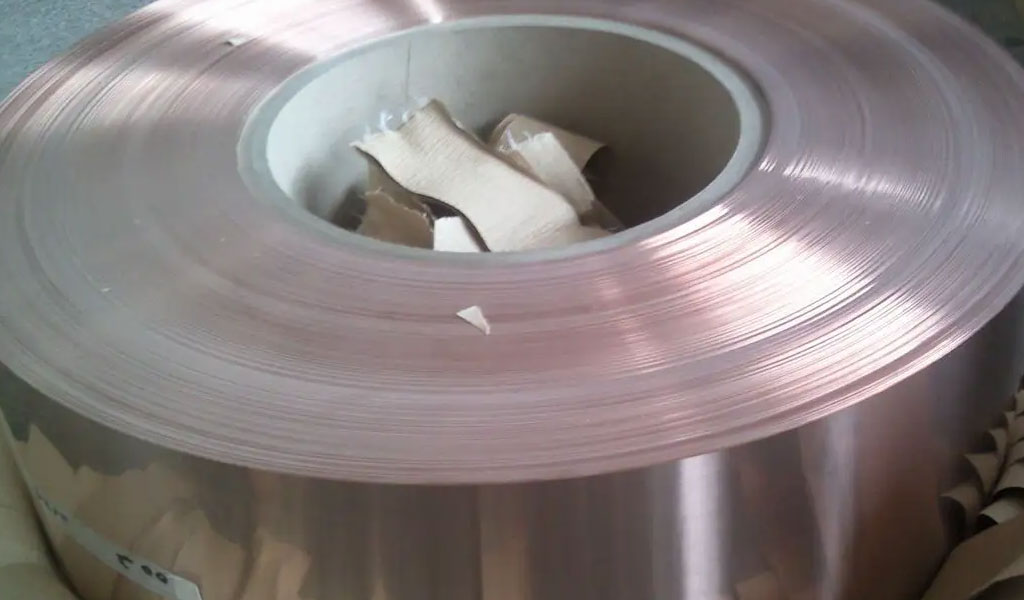

Aluminum alloys are lightweight and strong, suiting the metal for a wide range of applications.Multiple organizations view BE-CU as the best company offering photochemical etching aluminum alloys custom work, and we know how to etch aluminum to suit your application and ensure you benefit over other materials and processes.

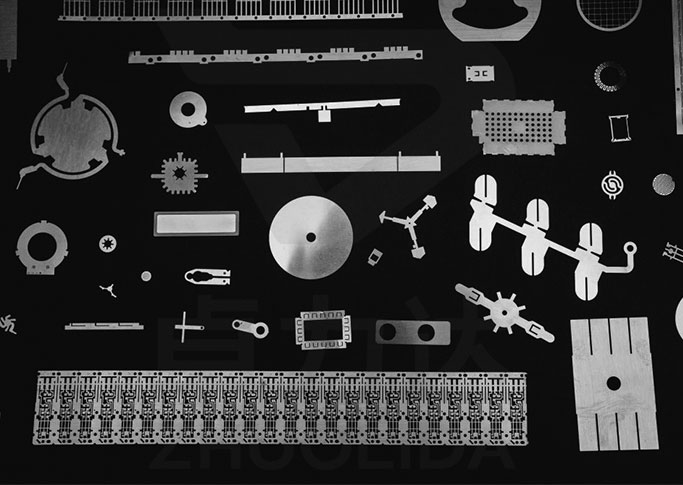

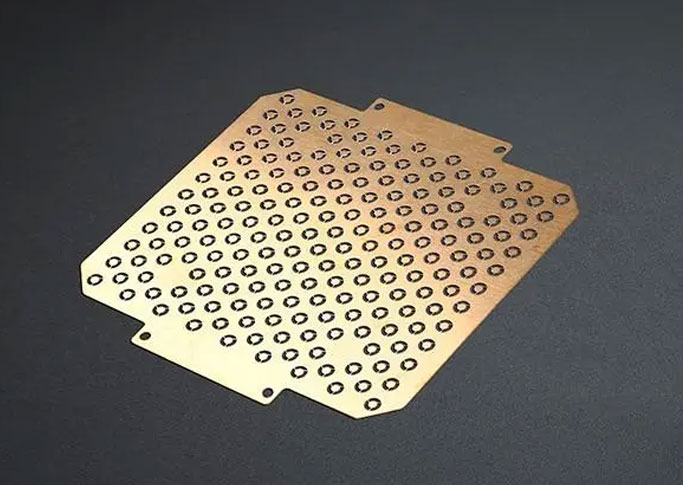

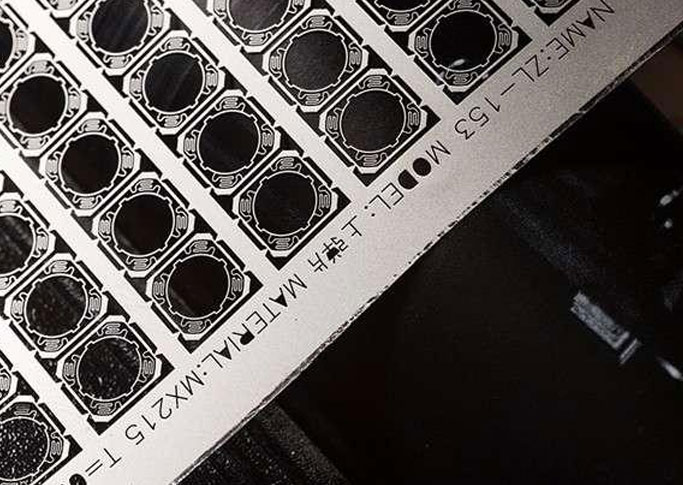

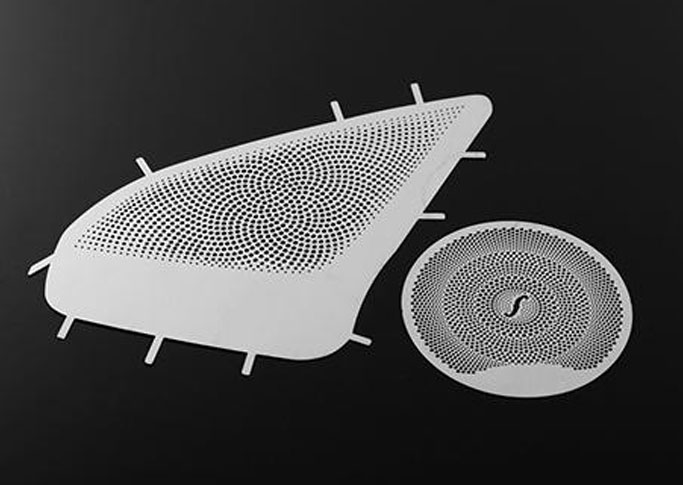

Chemical Milling

Chemical milling, also known as photochemical milling or chemical machining, also involves a masking compound and an etchant. During chemical milling, manufacturers start by covering a piece of sheet metal in an inert masking compound. Then, they bathe the metal in an appropriate etchant. As the exposed metal and etchant react, the etchant cuts via dissolution.