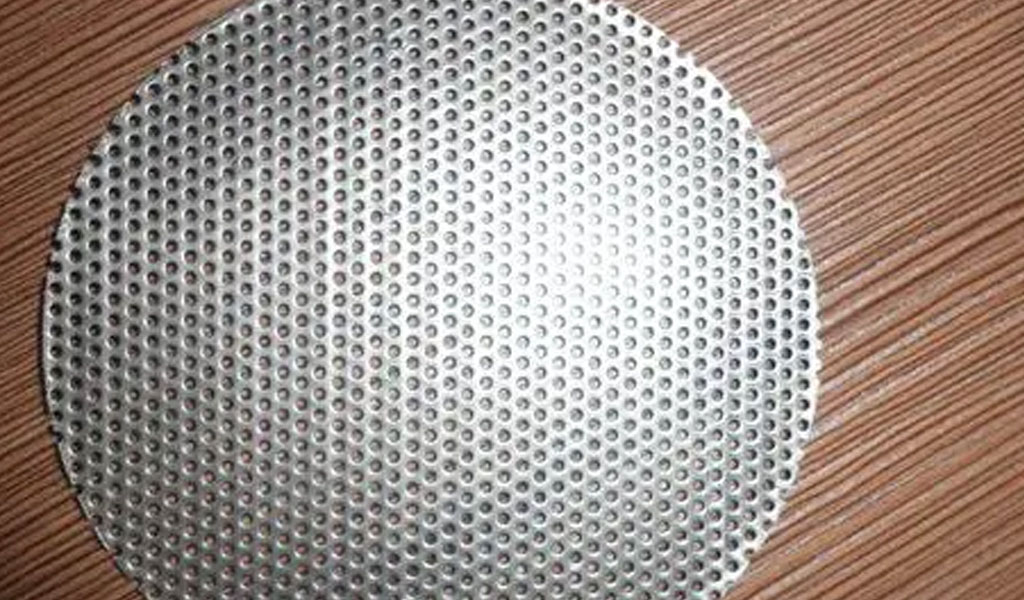

The processing of filter mesh is the most common processed product in daily life, and its precision is also constantly increasing. In the early days, filter meshes were processed by punching and laser processing. The pursuit of thickness precision has become smaller and smaller, resulting in the pursuit of the ultimate process. The punched micron mesh has a limit on thickness.

The process requirements cannot be met if it is less than 1MM. Punching will cause material fracture and holes. High-precision laser processing can achieve a 1MM aperture. Due to the laser burning method, some holes will have black spots. Subsequent surface treatment is required, such as polishing or plating, nickel plating for anti-corrosion effect, etc. Laser processing is relatively slow in batch processing and production.

Therefore, if the precision requirements and micron tolerances are extremely small, it is processed by chemical etching, using the chemical composition of ferric chloride to fuse with water to produce a high concentration of chemical agents. In the early stage of chemical etching, the metal material is degreased and polished, and then a layer of photosensitive ink is rolled on to protect the part that is not decomposed by the chemical agent.

The part that needs to be decomposed is exposed, and the prepared metal film pattern is developed and exposed to the metal material, and then the chemical etching process is entered to remove the photosensitive ink to form the desired metal finished product.

Why is etching chosen for micron tolerance mesh? The main reason is that the micron tolerance mesh etching process meets the processing requirements. The micron tolerance mesh etching processing thickness is between 0.01MM-2MM. The micron tolerance mesh etching surface is smooth and burr-free, maintaining product performance and not deforming. The metal film can be modified arbitrarily without increasing the processing cost, while the cost of punching mesh processing in designing the mold is relatively high.

Therefore, the best processing method for micron tolerance mesh can be chemical etching. Considering the mass production process, the price is low and meets high standard precision processing.

We Can Take Care Of Your Metal Etching Needs.

BE-CU metal etching china company’s strength lies in our investment in chemical etching production line. Chemical etching production line are the foremost innovation to the metal etching industry.

The programmability of Chemical etching production line gives us quick and accurate repeatability. This constant replication allows for better finishes, tighter tolerances and most importantly – faster cycles for metal forming.

By engaging our etching company, you can also get the much-needed support to design your part for any specific purpose. Our team can provide custom design tips, such as ensuring consistent wall thickness and avoiding overly thick sections that can sink.

Are you designing new products for projects companies? We can help! Here at BE-CU Metal Etching China Company, we offer a reasonably priced rapid metal etching service that will allow you to make an amazing prototype that will impress your clients. Get a free project review here so we can get started for your metal etching products!

- Photo Etching for Medical Use

- Photo Etching for Metal Sign

- Photo Etching for Jewelry

- Ferric Chloride Etching Stainless Steel

- The Best Acid for Etching Steel

- The Principle And Process Flow Of PCB Etching Machine

- In The Localization Of Wafer Foundry Equipment, Etching Machines Stand Out

- How Important is the Blind Hole Rate of Filter Screens?

- The whole process of stainless steel sheet etching

- What is the Role of Aperture Diaphragms in the Field of Optics?