Precision etching process requires pre-treatment of metal materials. Its main function is to improve the quality of the surface of the etched workpiece, remove various impurities on the surface, make the surface of the workpiece reach a certain roughness, and enhance the adhesion of the workpiece surface to prepare for the subsequent etching process.

Generally speaking, the pre-treatment of etching process needs to go through the following processing steps:

- Degreasing: The oil and grease on the surface of the precision etching workpiece will affect the infiltration and etching effect of the etching liquid, so degreasing is required. Degreasing generally uses chemical degreasing or ultrasonic degreasing to remove the grease and oil on the surface of the precision etching workpiece.

- Surface roughening: Surface roughening is a key step to improve the surface roughness of precision etching workpieces. Commonly used methods include mechanical roughening and chemical roughening. Mechanical roughening uses mechanical action to grind and polish the surface of the workpiece to make its surface rough; chemical etching uses chemical reactions to make the surface of the precision etching workpiece smooth and smooth without roughening.

- Sensitization treatment: Sensitization treatment is to put the workpiece into the sensitization solution to form a layer of reducing substances (such as Sn-Hg alloy) on the surface. This layer of substances can reduce the oxidant in the etching solution into a more active reducing agent, thereby enhancing the etching effect.

- Deoxidation film: During the sensitization process, a layer of oxide film will form on the surface of the workpiece, which will affect the wetting and etching effect of the etching solution. Therefore, deoxidation film treatment is required. Commonly used deoxidation film methods include pickling and mechanical deoxidation.

- Activation treatment: Activation treatment is a process performed after deoxidation film removal. The precision etching workpiece is placed in the activation solution to form a layer of hydrophilic substances on the surface. This layer of substances can enhance the wetting effect of the etching solution and improve the etching speed and uniformity.

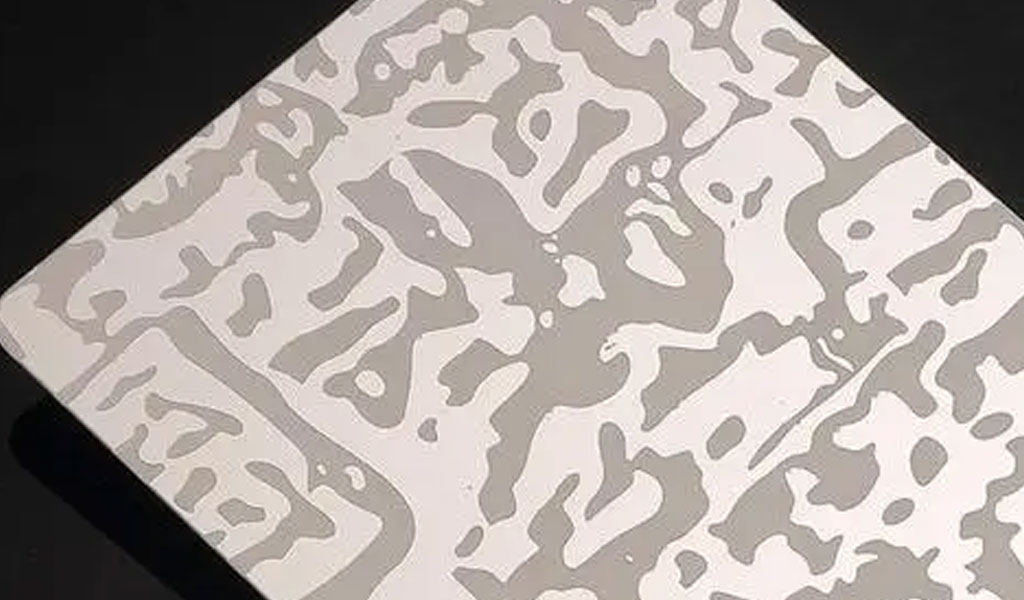

- Etching treatment: After the previous processes, the surface of the workpiece has become rough and hydrophilic, which lays a good foundation for etching treatment. During the etching process, it is necessary to select the appropriate etching solution type, concentration and temperature according to the specific product requirements to achieve the ideal etching effect.

- Post-processing: Post-processing is required after etching to clean the residue on the workpiece surface, remove thermal stress, etc. Common post-processing methods include water washing, pickling, heat treatment, etc.

In short, appropriate processing procedures before precision etching can improve the quality of the workpiece surface, remove impurities, enhance the adhesion of the workpiece surface, etc., and lay a good foundation for the subsequent precision etching process. Different processing procedures need to cooperate with each other to achieve the ideal processing effect.

We Can Take Care Of Your Metal Etching Needs.

BE-CU metal etching china company’s strength lies in our investment in chemical etching production line. Chemical etching production line are the foremost innovation to the metal etching industry.

The programmability of Chemical etching production line gives us quick and accurate repeatability. This constant replication allows for better finishes, tighter tolerances and most importantly – faster cycles for metal forming.

By engaging our etching company, you can also get the much-needed support to design your part for any specific purpose. Our team can provide custom design tips, such as ensuring consistent wall thickness and avoiding overly thick sections that can sink.

Are you designing new products for projects companies? We can help! Here at BE-CU Metal Etching China Company, we offer a reasonably priced rapid metal etching service that will allow you to make an amazing prototype that will impress your clients. Get a free project review here so we can get started for your metal etching products!

- Photo Etching for Medical Use

- Photo Etching for Metal Sign

- Photo Etching for Jewelry

- Ferric Chloride Etching Stainless Steel

- The Best Acid for Etching Steel

- The Principle And Process Flow Of PCB Etching Machine

- In The Localization Of Wafer Foundry Equipment, Etching Machines Stand Out

- How Important is the Blind Hole Rate of Filter Screens?

- The whole process of stainless steel sheet etching

- What is the Role of Aperture Diaphragms in the Field of Optics?