On March 29, SMIC’s application for the Science and Technology Innovation Board was approved, becoming the second semiconductor company to land on the Science and Technology Innovation Board after Jingchen, and the road to listing was officially opened.

On June 20, according to the information on the official website of the Shanghai Stock Exchange, SMIC obtained the qualification for issuance and listing (initial public offering).

SMIC’s road to the Science and Technology Innovation Board has attracted much attention. The main reason is that in the context of domestic high-end chips seeking domestic substitution, the localization of equipment will become the key, and SMIC itself is of great significance as a leader in semiconductor equipment. At the same time, the field of semiconductor etching machines, where SMIC is deeply rooted, is in a unique position in the domestic semiconductor equipment manufacturing industry and is known as the frontier of semiconductor equipment localization.

SMIC was established in 2004 and is mainly engaged in the field of semiconductor equipment. This includes the research and development, production and sales of key equipment such as metal etching china equipment, deep silicon etching equipment and thin film deposition (MOCVD) equipment for LED chips. Its prospectus shows that SMIC’s operating income reached 1.639 billion yuan in 2018.

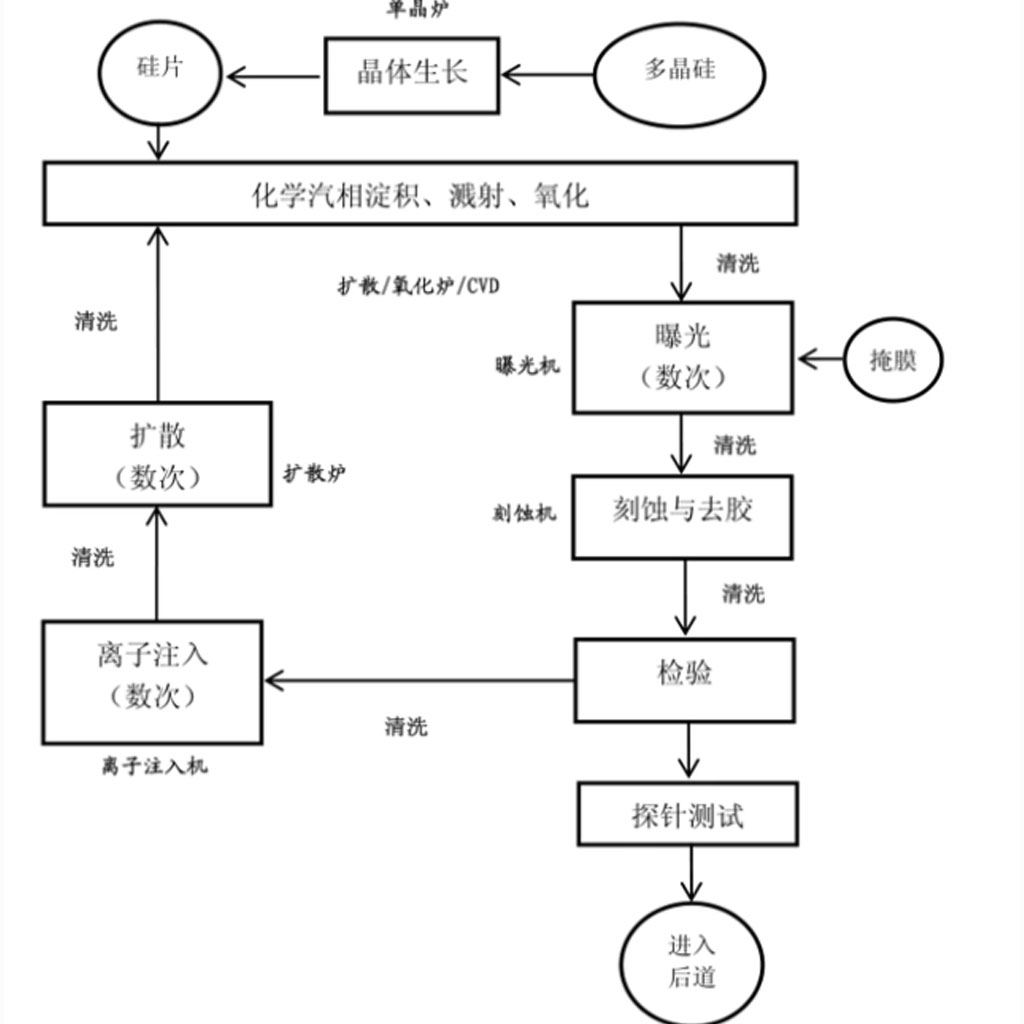

From the perspective of wafer manufacturing, the main process flow can be divided into oxidation-photolithography-etching-polishing-ion implantation-deposition-metallization-testing. As shown in the following figure:

Etching is the process of removing the top layer of the wafer by exposing the photoresist area. After mechanical processing such as slicing and grinding, the silicon wafer will form a mechanical stress damage layer with a certain depth, and the surface will be contaminated by impurities such as metal ions. Chemical corrosion is usually used to eliminate these effects. The current etching process is mainly divided into two categories: wet etching and dry etching. Simply put, wet etching is limited to graphic sizes above 2 microns, while dry etching is used in fine advanced circuits.

In the field of electrochemical etching machines, SMIC’s main business is capacitor plasma etching equipment (CCP) and inductive plasma etching equipment (ICP), which are two technical schools of etching machines.

The main international suppliers of etching machines are Applied Materials, Lam Research Semiconductor, etc. In December 2018, SMIC announced that its self-developed 5nm plasma etcher has been verified by TSMC and will be used in the world’s first 5nm process production line. However, the international market still presents a pattern of giants monopolizing the market. From a global perspective, the etching equipment market presents a situation of three dominant players: Lam Research occupies half of the market, with a market share of about 55%; Tokyo Electron is second, with a market share of about 20%; Applied Materials is equivalent to Tokyo Electron, with a market share of about 19%.

However, in the Chinese market, AMEC is gradually breaking the monopoly of international giants. The company’s prospectus shows that AMEC occupies a seat in the order share of etching factory purchased by two well-known domestic memory chip manufacturers, with order shares of 15% and 17% respectively. This is mainly because mainland etching equipment manufacturers have advantages in cost-effectiveness, service, and response speed on the newly built production lines of local wafer fabs, and breakthroughs are faster than foreign markets.

Taking the processor as an example, the processing steps required can reach hundreds of steps, and various types of processing equipment are advanced and expensive, starting at hundreds of millions of yuan. The equipment investment of a mature wafer foundry accounts for 70% to 80% of the total equipment. In terms of market structure, the global semiconductor equipment market is currently dominated by foreign manufacturers, and the industry presents a highly monopolistic competition pattern.

According to statistics from VLSI Research, global sales of semiconductor equipment systems and services in 2018 were US$81.1 billion. Among them, the top five semiconductor equipment manufacturers, due to their early start, have occupied 65% of the global semiconductor equipment market with their advantages in capital, technology, customer resources, and brand. Specifically in the field of etching machines where SMIC is located, China Merchants Securities estimates that etching equipment accounts for about 12% of the equipment value of the overall wafer equipment.

The value proportion of each equipment in wafer manufacturing is not large. Industry insiders analyze that the status and scale of etching machines in the entire semiconductor industry chain are on the rise. Because the structure on the chip is extremely small and complex, with the advancement of integrated circuit chip manufacturing technology, the line width continues to shrink, the chip structure is 3D, and wafer manufacturing is developing towards 7nm, 5nm and more advanced processes. The widespread use of immersion lithography machines is limited by wavelength. The processing of the microstructure of logic devices of 14nm and below will be achieved through a combination of plasma etching and thin film deposition processes-multiple module effects, which will increase the processing steps of related equipment. Beryllium copper etching equipment and thin film deposition equipment are expected to become more critical and the equipment with the highest investment share.

According to statistics from consulting firm Gartner, the global market share of SMIC’s capacitive etching equipment is about 1.4%. Therefore, although SMIC is a domestic leader, it still has a certain gap compared to global giants.

Another major product of SMIC is MOCVD equipment for LED chip manufacturing.

The so-called MOCVD, namely Metal-organic Chemical Vapor Deposition, forms an ultra-thin epitaxial coating layer on the semiconductor wafer after the interaction of high-purity metals or organic compounds. Since the epitaxial film layer determines the performance and quality of the LED light source, MOCVD equipment is the most expensive equipment in the LED chip manufacturing process, accounting for almost half of the cost of LED epitaxial chips.

According to statistics from LED Inside, China has become the world’s largest demand market for MOCVD. CITIC Securities Research Report pointed out that mainland China is the world’s largest LED chip production area, and its scale has increased from 47% in 2016 to 69% in 2108, far higher than the second-ranked Taiwan, China, 15% and the third-ranked South Korea, 5%.

In terms of market competition, as the price of LED bulbs gradually decreases, the profits that LED manufacturers can obtain are reduced, so they pay more attention to production efficiency. Tianfeng Securities report believes that the extremely high production efficiency of AMEC MOCVD has brought it a significant competitive advantage, because AMEC’s MOCVD equipment can operate in parallel or serial mode, reducing cross contamination, which is necessary for high-performance LED chips.

Before 2017, MOCVD equipment was mainly monopolized by two foreign manufacturers, Veeco in the United States and Aixtron in Germany. In 2017, AMEC’s MOCVD equipment gradually broke the monopoly of the above companies. The company’s second-generation Primo A7 MOCVD equipment has completely replaced Aixtron and Veeco’s equipment in China. According to HIS Market data, AMEC’s gallium nitride-based MOCVD equipment accounted for 41% of the global new equipment market in 2018.

The prospectus also shows that AMEC MOCVD equipment has been put into mass production on the production lines of many LED manufacturers such as Sanan Optoelectronics, Huacan Optoelectronics, and Ganzhao Optoelectronics, becoming the world’s top and domestically dominant gallium nitride-based LED MOCVD equipment manufacturer. Among the recent LED expansion manufacturers, most purchased SMIC MOCVD equipment, with a domestic market share of over 80%.

In the future, SMIC will continue to upgrade its technology and products. Among them, new high-capacity MOCVD equipment for the next generation of high-capacity blue-green light, and high-temperature MOCVD equipment for UVLED and silicon-based gallium nitride power devices have been initially developed. In terms of etching equipment, 7-14 nanometer CCP/ICP etching and high-end MEMS etching are also in the process of research and development, and have achieved phased results, which are expected to be completed in 2019 and beyond. The Science and Technology Innovation Board’s fundraising and investment projects also include the expansion, upgrade and research and development of these etching and MOCVD projects.

We Can Take Care Of Your Metal Etching Needs.

BE-CU metal etching china company’s strength lies in our investment in chemical etching production line. Chemical etching production line are the foremost innovation to the metal etching industry.

The programmability of Chemical etching production line gives us quick and accurate repeatability. This constant replication allows for better finishes, tighter tolerances and most importantly – faster cycles for metal forming.

By engaging our etching company, you can also get the much-needed support to design your part for any specific purpose. Our team can provide custom design tips, such as ensuring consistent wall thickness and avoiding overly thick sections that can sink.

Are you designing new products for projects companies? We can help! Here at BE-CU Metal Etching China Company, we offer a reasonably priced rapid metal etching service that will allow you to make an amazing prototype that will impress your clients. Get a free project review here so we can get started for your metal etching products!

- Photo Etching for Medical Use

- Photo Etching for Metal Sign

- Photo Etching for Jewelry

- Ferric Chloride Etching Stainless Steel

- The Best Acid for Etching Steel

- The Principle And Process Flow Of PCB Etching Machine

- In The Localization Of Wafer Foundry Equipment, Etching Machines Stand Out

- How Important is the Blind Hole Rate of Filter Screens?

- The whole process of stainless steel sheet etching

- What is the Role of Aperture Diaphragms in the Field of Optics?