Laser mesh and etched mesh, which one is better? This is a topic that many technology enthusiasts and industry experts have been arguing about. Today, let’s find out!

Laser mesh processing is fast and accurate, and can process smaller apertures, but the processing effect of larger and smaller holes is not as good as etching. Etching mesh processing is slow, but it is better for large-area hole processing due to the use of metal film and chemical corrosion, and the price is cheaper.

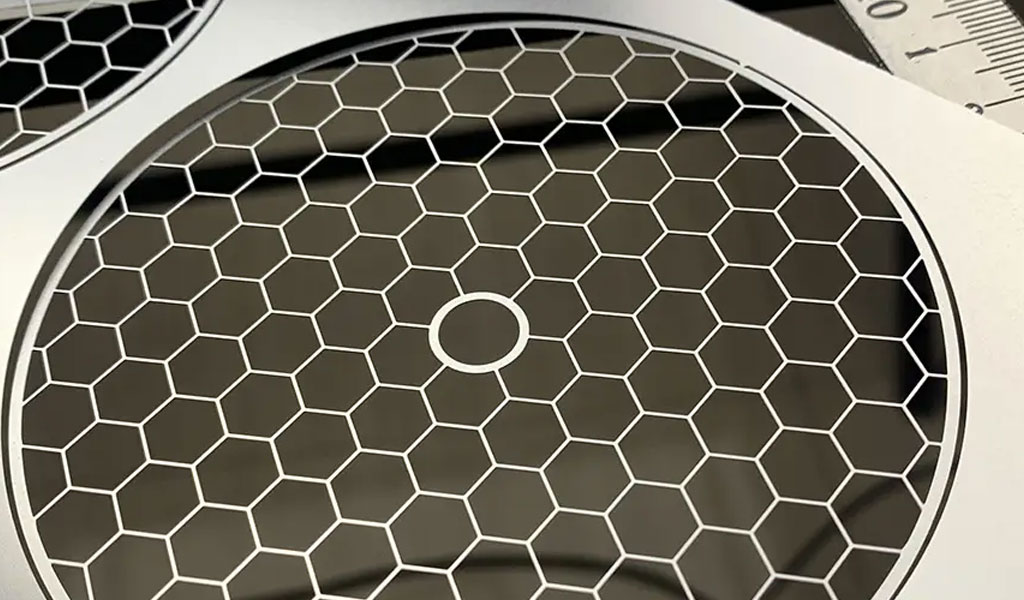

Laser mesh is a laser drilling method, which uses a high-energy laser beam to irradiate the surface of the material to produce a high-temperature area, and then achieves drilling through the gasification of the high-temperature area. The advantages of laser drilling are: high aperture accuracy, good hole quality, fast speed, can process various materials, suitable for thin plate materials, and can also be processed on complex curved surfaces. However, there are also some disadvantages, such as high cost, certain damage to materials, and unsuitable for processing ultra-thin or thick plate materials. In addition, laser processing requires high equipment and energy costs, while etching processing requires a large amount of chemicals, which pollutes the environment. As manufacturers with certain strength, they have established a sewage treatment circulation system to reduce pollution to national standard values. Etching mesh also has some disadvantages, such as slow speed, limited processing depth, and high material requirements, but it can achieve a material thickness between 0.01mm-2mm, and the processed mesh will not be deformed or burned by laser drilling, and the burrs on the side of the mesh processing. Therefore, enterprises need to consider cost and environmental factors when choosing a processing method. Laser mesh and etching mesh are not completely opposite, they have different applications in different fields.

In addition to cost and effect, another important factor is the difficulty of processing. Laser processing requires professional technicians and high-end equipment, while etching processing is relatively simple, and only requires a certain amount of chemical knowledge. Therefore, for companies that mass-produce functional products, etching mesh may be more suitable.

When choosing between laser mesh and etching mesh, you need to choose according to the actual situation. If high precision and small aperture are required, then laser mesh is a better choice; if low cost and large processing area are required, then etching mesh is more suitable. No matter which method is chosen, we need to pay attention to environmental protection and cost control, so that scientific and technological progress and sustainable development complement each other.

We Can Take Care Of Your Metal Etching Needs.

BE-CU metal etching china company’s strength lies in our investment in chemical etching production line. Chemical etching production line are the foremost innovation to the metal etching industry.

The programmability of Chemical etching production line gives us quick and accurate repeatability. This constant replication allows for better finishes, tighter tolerances and most importantly – faster cycles for metal forming.

By engaging our etching company, you can also get the much-needed support to design your part for any specific purpose. Our team can provide custom design tips, such as ensuring consistent wall thickness and avoiding overly thick sections that can sink.

Are you designing new products for projects companies? We can help! Here at BE-CU Metal Etching China Company, we offer a reasonably priced rapid metal etching service that will allow you to make an amazing prototype that will impress your clients. Get a free project review here so we can get started for your metal etching products!

- Photo Etching for Medical Use

- Photo Etching for Metal Sign

- Photo Etching for Jewelry

- Ferric Chloride Etching Stainless Steel

- The Best Acid for Etching Steel

- The Principle And Process Flow Of PCB Etching Machine

- In The Localization Of Wafer Foundry Equipment, Etching Machines Stand Out

- How Important is the Blind Hole Rate of Filter Screens?

- The whole process of stainless steel sheet etching

- What is the Role of Aperture Diaphragms in the Field of Optics?