Have you ever thought that cars in the future will be like science fiction movies, without a trace of exhaust, and powered entirely by a mysterious fuel? Today, let us explore the mystery of this new fuel-hydrogen fuel!

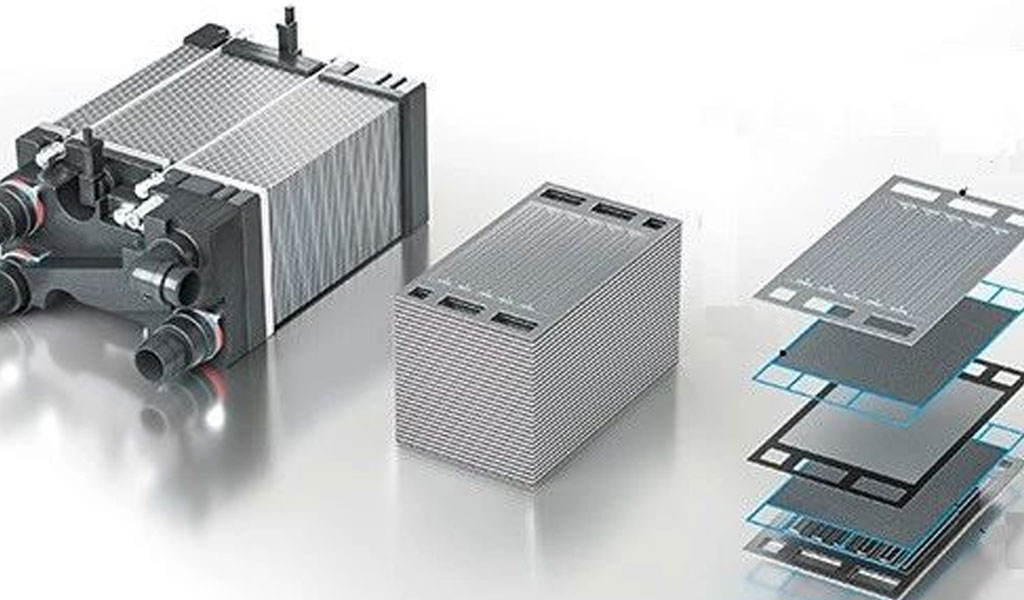

Hydrogen fuel is a green and clean energy source. Its combustion process only produces water vapor and is very environmentally friendly. Not only that, hydrogen fuel cells have high energy density, can provide long-lasting power, and have short charging time, which is crucial for long-distance vehicles. In hydrogen fuel cells, titanium bipolar plates for hydrogen production from hydrogen fuel are a key material. This material has the advantages of high strength, high corrosion resistance, and high conductivity, which can significantly improve battery performance and life. More importantly, the hydrogen fuel hydrogen production titanium bipolar plate can also reduce the cost of the battery, making it more market competitive.

The etching process of hydrogen production bipolar plates is a very complex process that requires multiple processes to complete. First, the bipolar plates are cut into the desired shape and then surface treated to improve their corrosion resistance. Next, the bipolar plate will be placed in concentrated sulfuric acid for etching. By controlling the temperature, pressure, and speed of the acid, the bipolar plate can be etched with precise patterns and slots. Finally, the bipolar plates are cleaned, dried and assembled.

The etching process of hydrogen production bipolar plates not only requires craftsmen to have rich experience and skills, but also requires continuous upgrading and improvement of equipment and technology. Only in this way can high-quality bipolar plates be produced, providing a strong guarantee for the promotion and use of hydrogen fuel cell vehicles.

We Can Take Care Of Your Metal Etching Needs.

BE-CU metal etching china company’s strength lies in our investment in chemical etching production line. Chemical etching production line are the foremost innovation to the metal etching industry.

The programmability of Chemical etching production line gives us quick and accurate repeatability. This constant replication allows for better finishes, tighter tolerances and most importantly – faster cycles for metal forming.

By engaging our etching company, you can also get the much-needed support to design your part for any specific purpose. Our team can provide custom design tips, such as ensuring consistent wall thickness and avoiding overly thick sections that can sink.

Are you designing new products for projects companies? We can help! Here at BE-CU Metal Etching China Company, we offer a reasonably priced rapid metal etching service that will allow you to make an amazing prototype that will impress your clients. Get a free project review here so we can get started for your metal etching products!

- Photo Etching for Medical Use

- Photo Etching for Metal Sign

- Photo Etching for Jewelry

- Ferric Chloride Etching Stainless Steel

- The Best Acid for Etching Steel

- The Principle And Process Flow Of PCB Etching Machine

- In The Localization Of Wafer Foundry Equipment, Etching Machines Stand Out

- How Important is the Blind Hole Rate of Filter Screens?

- The whole process of stainless steel sheet etching

- What is the Role of Aperture Diaphragms in the Field of Optics?