Industrial metal chemical corrosion processing usually involves the following four steps:

- (1) Cleaning: The material to be corroded is subjected to surface treatment on the blank to remove various stains and oil stains and keep the surface clean. The material is selected mainly according to the type of metal material and the degree of contamination on the surface of the material to ensure that the anti-corrosion layer can adhere to the metal surface uniformly and the etching speed is uniform. Organic solvent cleaning, alkaline chemical and acid cleaning, ultrasonic and electrolytic cleaning, etc. are usually used.

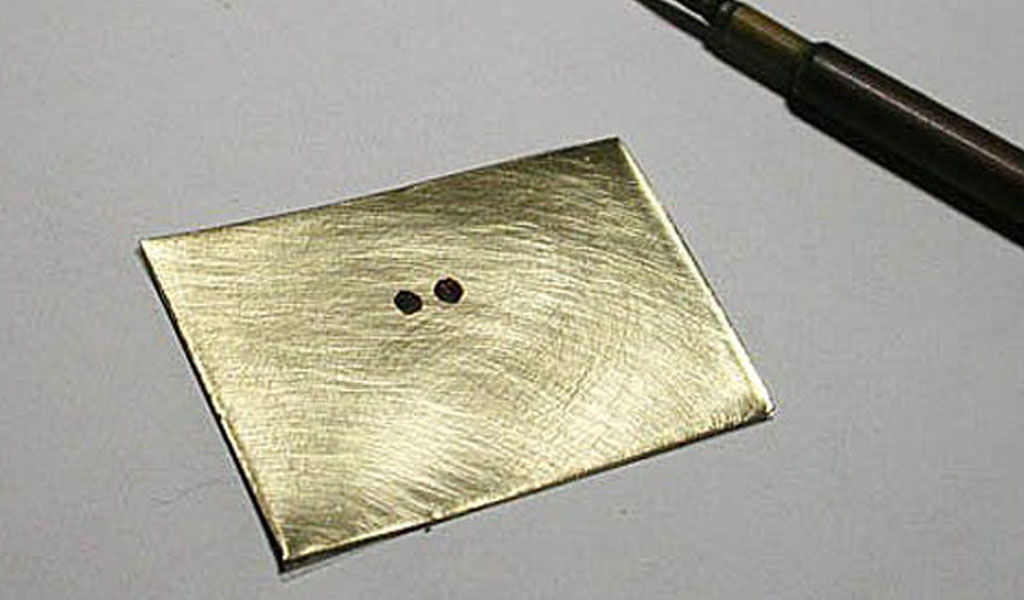

- (2) Anti-corrosion treatment: The surfaces that do not need to be corroded are protected by photosensitive ink, so that the metal surfaces that need to be corroded are completely exposed and corroded by the corrosive agent suitable for the metal material. The anti-corrosion material, i.e., photosensitive ink, must adhere firmly to the metal surface and the anti-corrosion layer will not fall off during the entire corrosion process.

- (3) Corrosion processing: The main control of the process: corrosive agent concentration, corrosion temperature, etching time, etc. After the anti-corrosion pattern is made according to the requirements of the drawing, the corroded metal material is placed in the corrosion tank for etching.

- (4) Removing the anti-corrosion layer: After the etching process is completed, the surface of the component is stripped by solvents, alkali solutions or other cleaning agents to remove the anti-corrosion layer.

We Can Take Care Of Your Metal Etching Needs.

BE-CU metal etching china company’s strength lies in our investment in chemical etching production line. Chemical etching production line are the foremost innovation to the metal etching industry.

The programmability of Chemical etching production line gives us quick and accurate repeatability. This constant replication allows for better finishes, tighter tolerances and most importantly – faster cycles for metal forming.

By engaging our etching company, you can also get the much-needed support to design your part for any specific purpose. Our team can provide custom design tips, such as ensuring consistent wall thickness and avoiding overly thick sections that can sink.

Are you designing new products for projects companies? We can help! Here at BE-CU Metal Etching China Company, we offer a reasonably priced rapid metal etching service that will allow you to make an amazing prototype that will impress your clients. Get a free project review here so we can get started for your metal etching products!

- Photo Etching for Medical Use

- Photo Etching for Metal Sign

- Photo Etching for Jewelry

- Ferric Chloride Etching Stainless Steel

- The Best Acid for Etching Steel

- The Principle And Process Flow Of PCB Etching Machine

- In The Localization Of Wafer Foundry Equipment, Etching Machines Stand Out

- How Important is the Blind Hole Rate of Filter Screens?

- The whole process of stainless steel sheet etching

- What is the Role of Aperture Diaphragms in the Field of Optics?