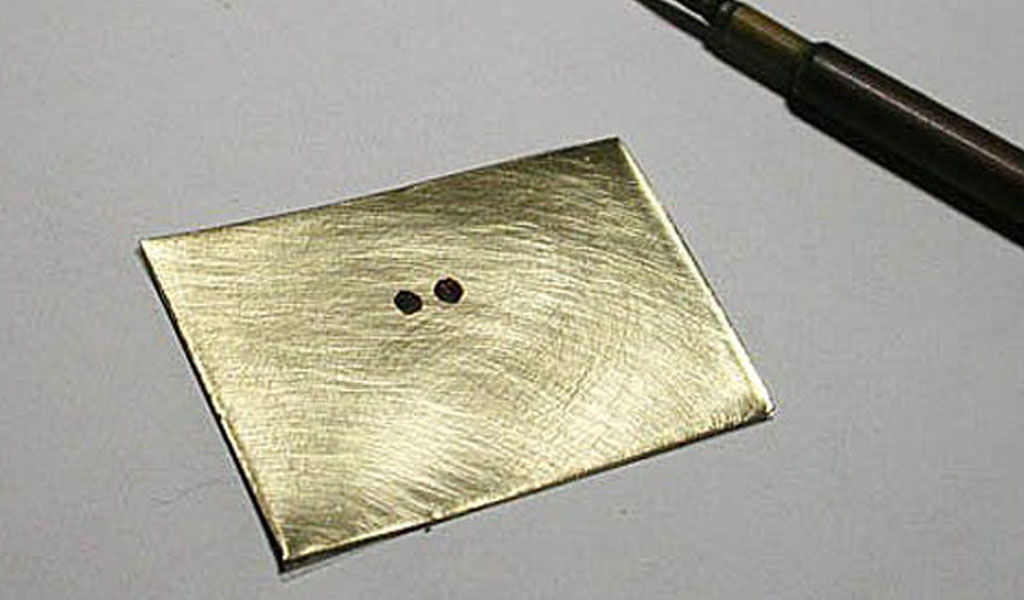

There are many ways to process the speaker mesh. The traditional processing uses stamping technology. The edge of the punched speaker mesh has certain burrs. The ultra-thin products use stamping…

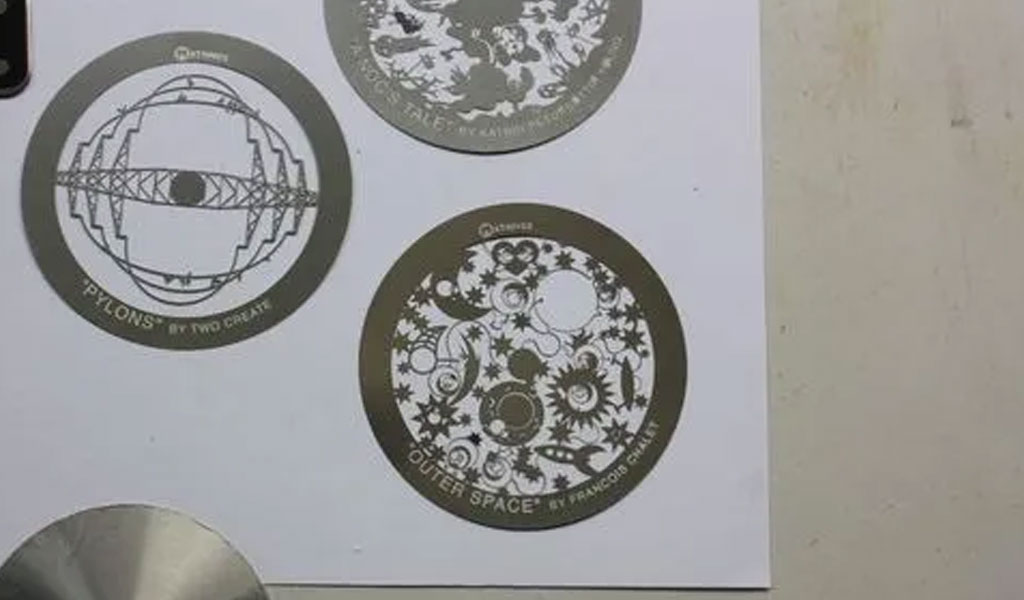

How to choose the processing method for car horn mesh

There are many ways to process the speaker mesh. The traditional processing uses stamping technology. The edge of the punched speaker mesh has certain burrs. The ultra-thin products use stamping…

Etching and laser processing are two different processing methods, and their functions and application scenarios are also different. Next, let's take a closer look at the differences between etching and…

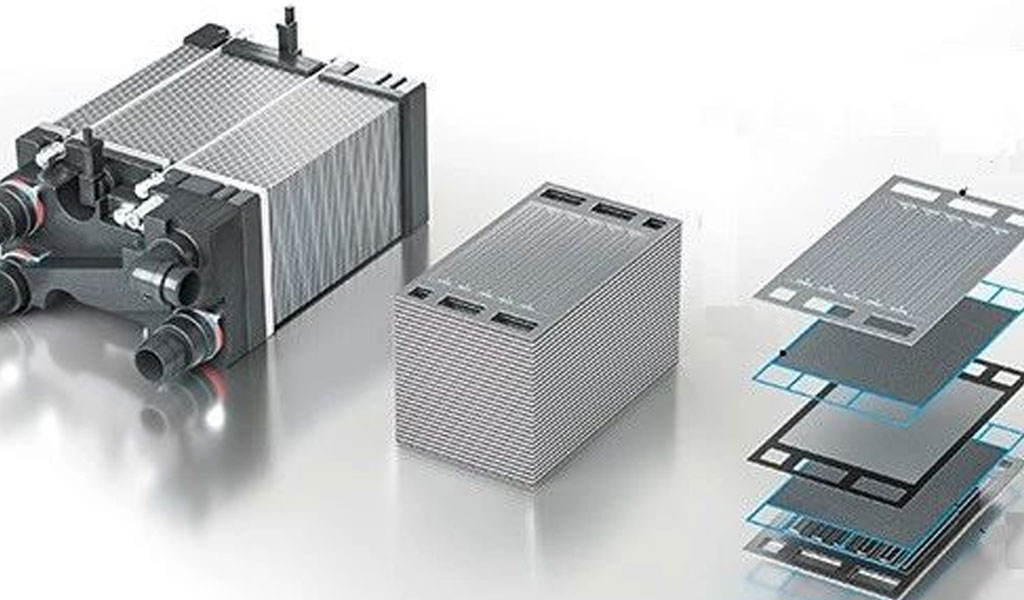

Have you ever thought that cars in the future will be like science fiction movies, without a trace of exhaust, and powered entirely by a mysterious fuel? Today, let us…

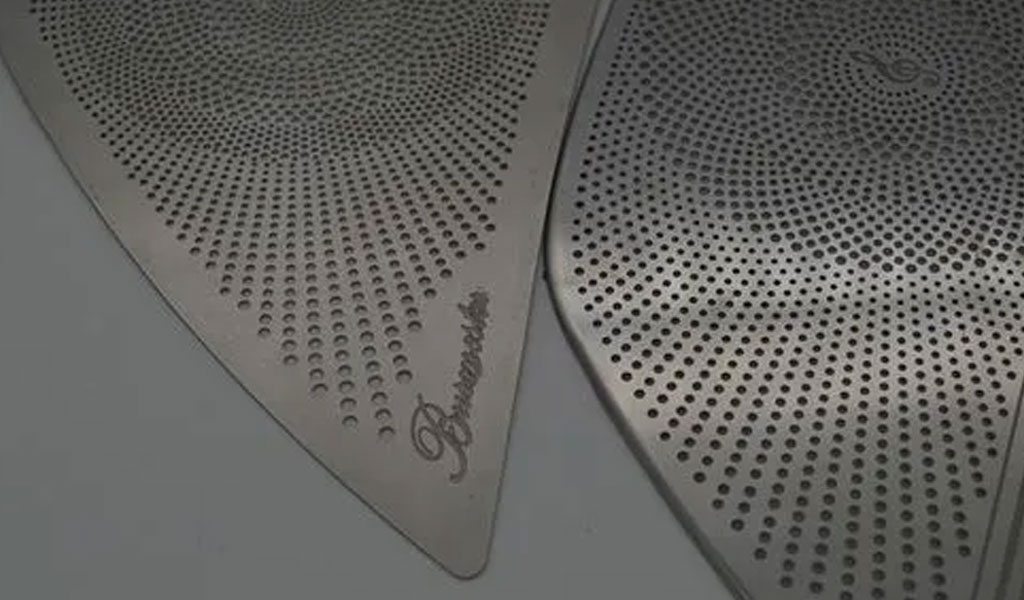

Industrial metal chemical corrosion processing usually involves the following four steps: (1) Cleaning: The material to be corroded is subjected to surface treatment on the blank to remove various stains…

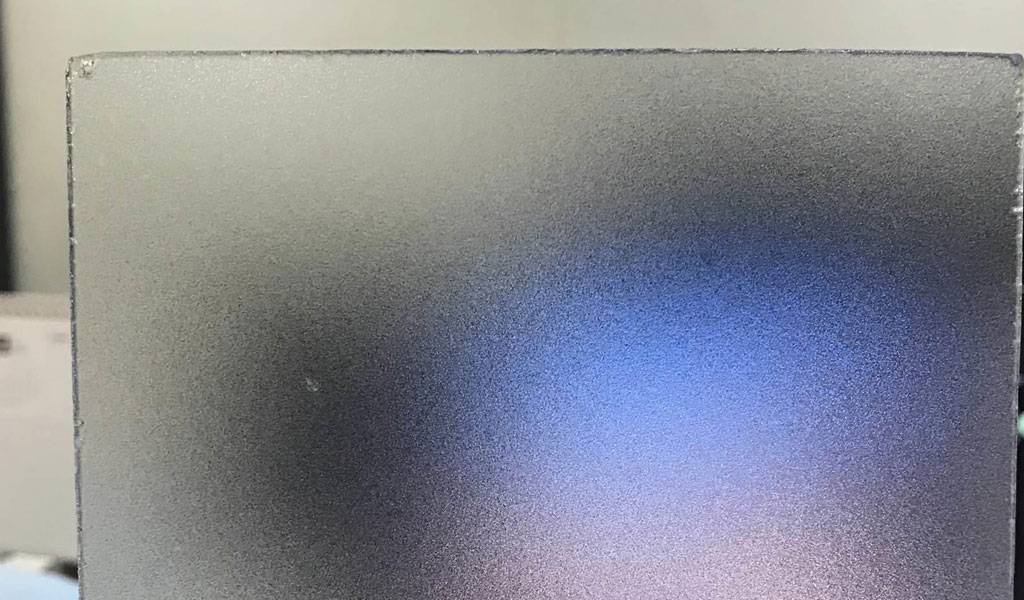

Etching speed and side etching amount are the most important parameters in the chemical etching process. Side etching amount determines the precision of chemical etching. The smaller the side etching…

Chemical etching can only be used as a benchmark for progressive cutting based on the original surface state of the part. The shape and surface state of the part after…

Chemical etching is based on the original surface of the part. Unlike most mechanical processing methods, it is not based on the reference surface of the metal cutting machine tool…

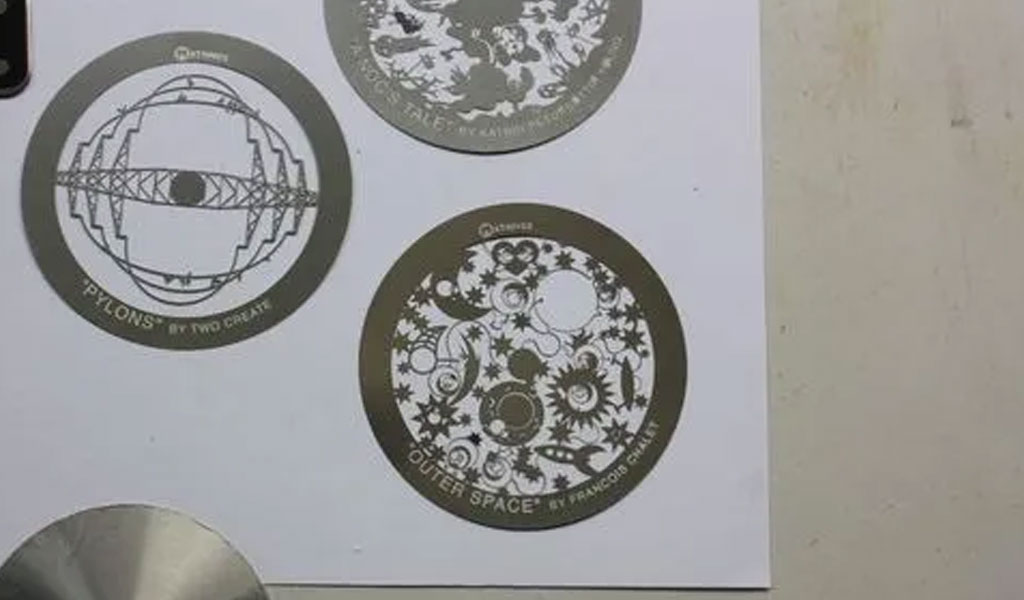

Anti-corrosion technology is to copy the selected image to the surface of the metal part that needs to be etched through photochemical imaging technology, screen printing technology, image electroplating technology,…

Chemical corrosion refers to corrosion damage caused by purely chemical interactions between metallic materials and non-electrolytes. The characteristics of the reaction process are: a direct oxidation-reduction reaction occurs between the…

Etching stainless steel has the advantages of high precision, high flatness, no deformation, strong adaptability, environmental protection and safety. It is a very excellent processing method. There are many ways…